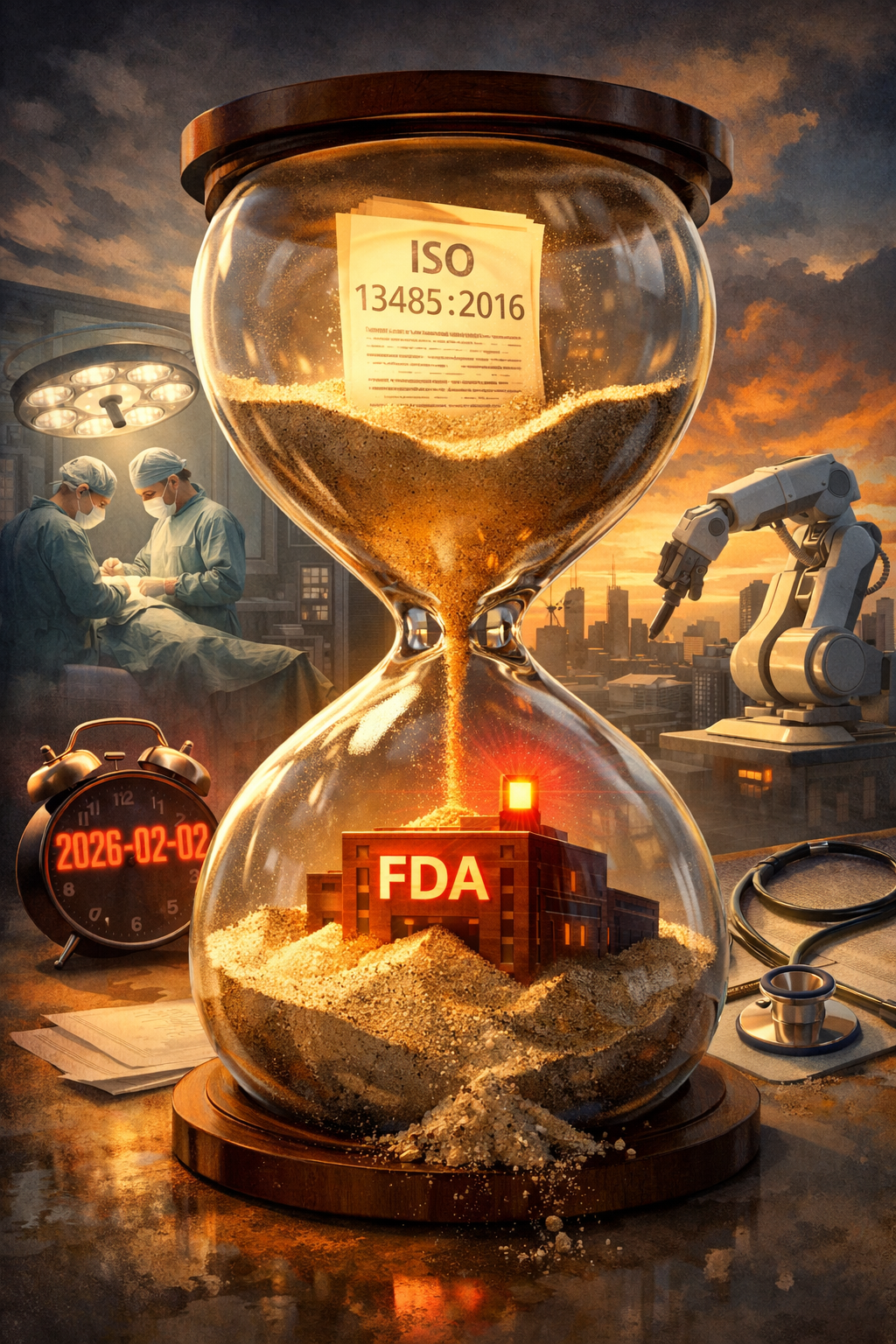

A Deep Dive into ISO 13485 Requirements for Medical Devices

The International Organization for Standardization (ISO) has developed a comprehensive set of standards, ISO 13485, designed specifically to uphold and enhance the quality and safety of medical devices. By thoroughly understanding the ISO 13485 requirements, businesses can facilitate a smoother ISO 13485 certification process, ensure optimal ISO 13485 compliance, and improve their overall contribution to the health care sector.

Deep Dive into ISO 13485 Requirements

The primary objective of ISO 13485 requirements is to establish a functional framework for manufacturers that ensures their medical devices consistently meet both customer and regulatory expectations. These requirements are extensive, encompassing every aspect of a medical device's lifecycle. This includes the initial stages of design and development, to production, installation, and servicing.

Furthermore, the standard emphasizes the importance of post-market surveillance, corrective actions, and preventive actions. These elements of the ISO 13485 requirements focus on the continual improvement of product safety and performance, ensuring that devices remain effective and safe even after they've reached the market.

A firm understanding of these requirements is crucial for any organization operating in the medical device field, as they ensure that manufacturers prioritize safety, quality, and efficacy, thereby benefiting both the end-users and the health sector as a whole.

The Journey to ISO 13485 Certification

Pursuing ISO 13485 certification is a clear indication of a firm's commitment to maintaining high-quality medical devices. The certification process involves a thorough external audit, during which an independent certification body scrutinizes a company's processes and systems. This audit aims to confirm that these systems meet all ISO 13485 requirements.

Achieving ISO 13485 certification can provide a significant competitive advantage in the market. The certification is internationally recognized and respected, signaling to customers and regulatory bodies alike that the company is dedicated to maintaining high-quality standards and safety.

However, the certification is not a one-time event. To maintain the certification, companies must continue to meet the ISO 13485 requirements, including regular audits to demonstrate ongoing compliance. This commitment to sustained quality and safety can significantly enhance a company's reputation and customer trust.

The Role of an ISO 13485 Quality Management System

A crucial aspect of achieving and maintaining ISO 13485 compliance is the establishment of an effective Quality Management System (QMS). An ISO 13485 Quality Management System is a structured, documented set of procedures and policies. These guidelines are designed to standardize processes and manage risk effectively.

The QMS under ISO 13485 should primarily focus on ensuring product safety, meeting regulatory requirements, and achieving customer satisfaction. However, it should also promote a culture of continuous improvement. This culture encourages businesses to consistently seek better ways to meet the ISO 13485 requirements and improve their overall operations.

ISO 13485 Training: A Catalyst for Compliance and Certification

Understanding the intricacies and successfully implementing ISO 13485 requirements can be a challenging task. That's where ISO 13485 training comes into play. This training provides participants with a comprehensive understanding of the standards and assists them in learning how to apply these regulations in their organization effectively.

ISO 13485 training isn't only for compliance officers or quality managers. Anyone involved in the process, from executives to engineers and internal auditors, can benefit from ISO 13485 training. This comprehensive understanding can improve the company's overall compliance and potential for certification.

In conclusion, ISO 13485 requirements offer a robust framework for maintaining and enhancing the quality and safety of medical devices. By seeking ISO 13485 certification, implementing a robust Quality Management System, and investing in ISO 13485 training, companies can ensure they are compliant and capable of delivering safe and effective medical devices. It's a significant commitment, but one that serves a vital purpose: ensuring the safety and efficacy of medical devices that countless individuals rely on for their health and well-being.

The Value of ISO 13485 Certification

Obtaining ISO 13485 certification holds numerous benefits for an organization beyond just meeting regulatory requirements. Firstly, the process of certification can lead to improved business operations and product quality. It requires an organization to thoroughly review and optimize its processes, potentially identifying areas of improvement that might have been overlooked.

Secondly, the certification can boost an organization's reputation within the industry. Being ISO 13485 certified sends a powerful message to stakeholders, including customers, suppliers, and regulatory bodies, about the company's commitment to quality and safety. This could lead to increased business opportunities, especially in international markets where ISO 13485 is recognized.

Finally, becoming ISO 13485 certified could potentially increase customer trust and satisfaction. When customers know that a company has taken steps to ensure the quality and safety of its products, they are likely to have more confidence in using the devices and, by extension, more trust in the organization as a whole.

Tailored ISO 13485 Training

Given the complexity and breadth of ISO 13485, it is highly beneficial to undertake ISO 13485 training tailored to an organization's unique needs. Such training could range from comprehensive courses covering the entirety of ISO 13485, to more specific training focused on particular aspects such as risk management or the role of management within a QMS.

The most effective training programs are those that combine theoretical knowledge with practical application. This ensures that participants not only understand the requirements of ISO 13485 but can also apply this knowledge effectively within their organization's context. With such training, an organization can better navigate its ISO 13485 certification journey and maintain a robust, compliant QMS.

In Conclusion

ISO 13485 requirements provide an essential framework for companies involved in the manufacture of medical devices, paving the way for high standards of quality and safety. It's a rigorous journey towards ISO 13485 certification, but one that brings significant benefits. From demonstrating commitment to quality and safety to regulatory bodies and customers, to improving processes and systems within an organization, it's a journey well worth taking.

With the establishment of a robust ISO 13485 Quality Management System and comprehensive ISO 13485 training, companies can ensure they stay on the path of compliance, continually striving for excellence in their delivery of safe and effective medical devices. ISO 13485 is more than just a standard; it's a commitment to quality, safety, and continuous improvement, values that lie at the heart of the medical device industry.

Here are some authoritative sources where you can find further information about ISO 13485 requirements for medical devices:

- ISO 13485:2016 - Medical Devices - Quality Management Systems - Requirements for Regulatory Purposes - ISO Official Website, this is the official page for ISO 13485:2016 on the ISO's website. It provides an overview of the standard and its requirements, and is a reliable source for updates or changes.

- ISO 13485 - Medical Devices - British Standards Institution (BSI), BSI is a business standards company that offers certification services among other things. Their page on ISO 13485 provides a wealth of information, including the benefits of certification and how to get certified.